The story of rock crushers is as old as civilization itself. As humans evolved and started forming communities, there emerged a need for tools to aid in the construction of shelters, and to pave the way for agriculture. One such fundamental tool is the rock crusher. Through the ages, rock crushers have seen dramatic transformations, and their mechanics have become more sophisticated with each passing era.

Ancient Beginnings of Rock Crushing

Before there were machines, humans used primitive methods to break down rocks.

- Stones and Hammers: The earliest form of rock crushers were two stones – one stationary and the other portable. Humans would hit rocks with the portable stone, breaking them down.

- Lever and Pit Mechanism: Over time, they introduced the lever mechanism. A large rock would be placed in a pit and a long wooden lever would be used to apply pressure, cracking the rock.

Middle Ages – The Advent of Mechanical Advantage

The Middle Ages saw considerable advances in the mechanics of rock crushers, mainly due to the innovations brought by the Industrial Revolution.

- Water Wheels and Windmills: These energy sources began to be harnessed for crushing rocks. The rotary motion provided by the water wheel was transferred to crushing devices.

- Stamp Mills: These mills used large heavy rods or ‘stamps’ to crush rocks – a method particularly popular in mining regions.

The 19th Century – A Period of Rapid Innovation

The 19th century was particularly transformative for the design and mechanics of rock crushers.

Steam Engines

- Piston-Driven Crushers: With the advent of steam engines, piston-driven crushers became prevalent. These machines used steam power to drive a piston which crushed rocks against a fixed plate.

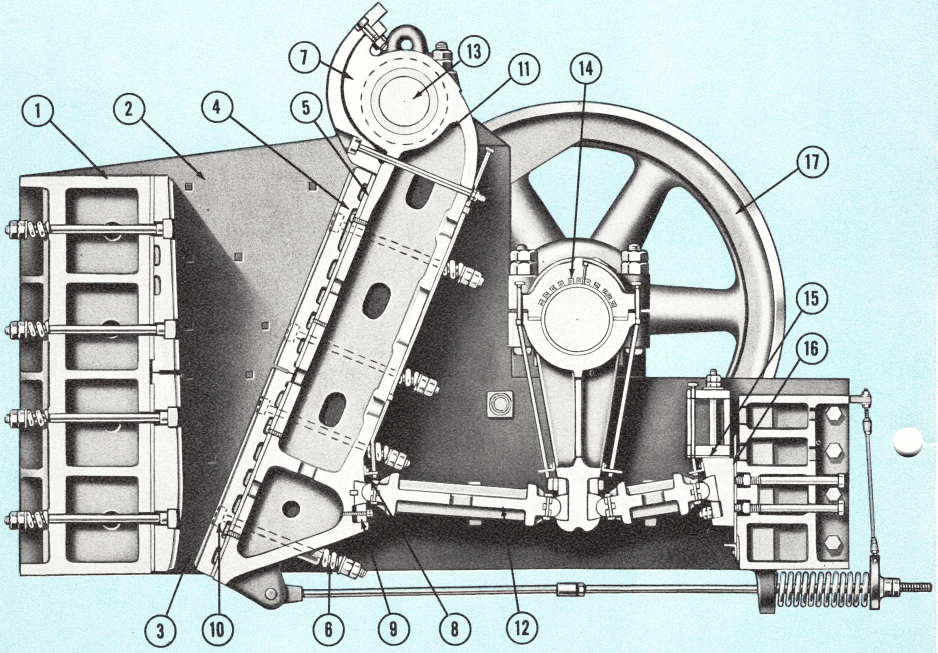

The Blake Jaw Crusher

- Inception in 1858: One of the most famous rock crushers of the 19th century was the Blake Jaw Crusher, introduced by Eli Whitney Blake. This mechanism used a toggle and pitman arm setup to generate a powerful crushing action.

- Significance: Blake’s design laid the groundwork for the many variations of rock crushers in use today.

The 20th Century – Towards Automation and Modernization

The dawn of the 20th century ushered in a new era for rock crushers, with a focus on efficiency and automation.

- Electrical Power: As electricity became widely accessible, rock crushers transitioned from steam to electrical power, leading to more efficient and consistent operations.

- Cone Crushers: These evolved from the earlier designs and provided a more uniform size of the crushed product. They became widely popular for their efficiency.

- Impact Crushers: A modern solution for more specific needs, impact crushers use a spinning rotor with bars or hammers that throw the rock against hard surfaces to break it.

The 21st Century – Digitization and Advanced Mechanics

Computer Integration

- Sensors and Feedback Loops: Modern rock crushers are now integrated with computer systems that use sensors to monitor operations. These systems can make real-time adjustments to optimize performance.

- Predictive Maintenance: With the integration of AI, these crushers can now predict when they might fail, ensuring that maintenance can be done proactively.

Mobile Rock Crushers

- Portability: With the need for more flexible operations, especially in mining, mobile rock crushers have become prominent. These can be moved to different locations, ensuring that rock crushing can be done on the spot, reducing transportation costs.

Conclusion – The Ever-Evolving World of Rock Crushers

From primitive stone-on-stone crushing to today’s computer-integrated, mobile machinery, rock crushers have undergone immense evolution. Each advancement, from the basic lever mechanism of ancient times to the sophisticated electronics of today, has been driven by humanity’s incessant need to harness nature for progress. As we look to the future, it is certain that rock crushers will continue to adapt and serve as an indomitable tool in the realm of construction and mining.