The automated logic RS Pro temperature sensor is a device for non-contact surface temperature measurement of solids or liquids. The RS standard is a thermostat-based temperature sensor. The small size makes it ideal for installation in tight spaces. Sensors work by detecting infrared energy emitted by an object. Temperature can be obtained digitally via UART using the Modbus RTU protocol or monitored continuously via DC output. It uses industrial process instruments and also has a configurable alarm output.

The components of R Pro and RS Standard are as follows.

1. Target size

The measurement spot size should not be larger than the target. The sensor should be positioned so the measured spot size is smaller than the target.

2. Digital screen

The digital display shows Celsius values with an accuracy of 0.5 degrees. The digital display displays Fahrenheit values to the nearest full degree. Occupied indicates when the regular schedule or manual override occupies the zone.

3. Ambient temperature

The measuring head can be used up to an ambient temperature of 70 °C. Avoid thermal shock, and wait 20 minutes for the device to adapt to the large change in ambient temperature.

4. Air quality

Smoke, dust, and vapors can contaminate the lens and cause erroneous temperature readings. The optional air purge collar should be used in such environments to keep the lens clean.

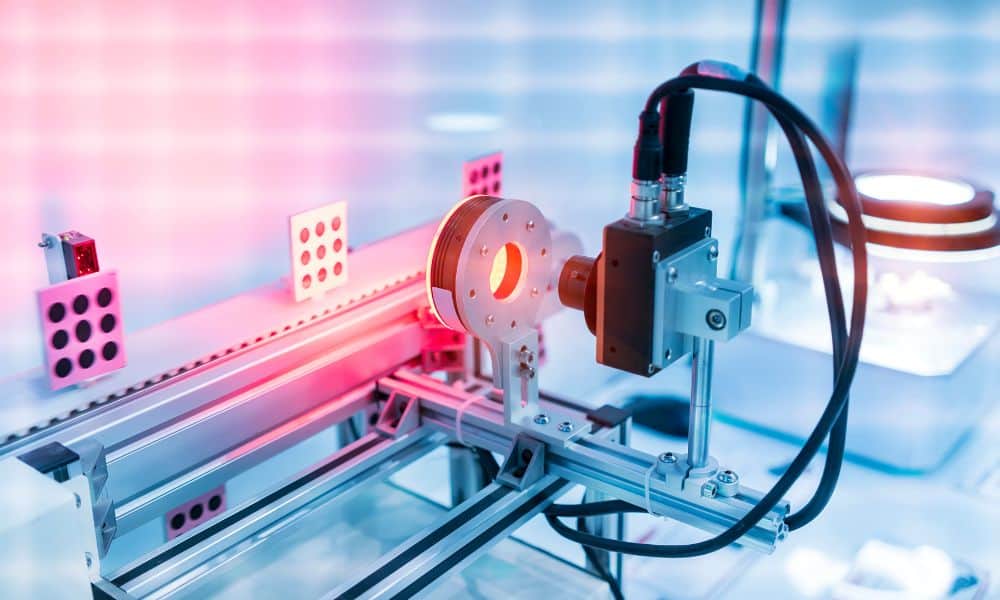

5. Mechanical equipment

Sensors can be attached to mounts or mounts of a design. One can also use the optional mounting accessories shown below. Attach the sensor to a mounting plate or bracket with a third center hole to “see” the sensor using two M3 mounting screws (included). Drilling 13-16mm diameter holes for mounting plates up to 2mm thick is recommended. Ensure the mounting does not block the sensor’s field of view (FOV). Please refer to the optical chart for specs and leave a clear area twice as high as the FOV cone for the best accuracy.

6. Setpoint adjustment

Heat and cool buttons allow occupants to change zone settings. Press “warmer” or “cooler” to view the current average heating and cooling settings. Pressing [Warmer] or [Cooler] again will increment or decrement both settings by the amount set in the RS macroblock property page and display the new average settings.

What are the technical instructions for the automated logic RS Pro and RS Standard?

- If the sensor is exposed to a large change in ambient temperature (from hot to cold or cold to hot), allow 20 minutes for the body temperature of the sensor to stabilize before taking or recording measurements.

- Do not operate the sensor near strong electromagnetic fields (such as near arc welders or induction heaters). Electromagnetic interference can lead to measurement errors.

- Wires should only be connected to the correct terminals. Check all connections before applying power.

- Do not damage the cables. Moisture or steam can enter the sensor.

- Always switch off the device before changing electrical connections.

- Do not try to open the sensor. There are no user-serviceable parts inside. It will damage the sensor and void your warranty.

Conclusion

So these are the technical instructions for the R Pro and RS Standard sensors. Before installing a used or new thermostat, it is necessary to check for these instructions.